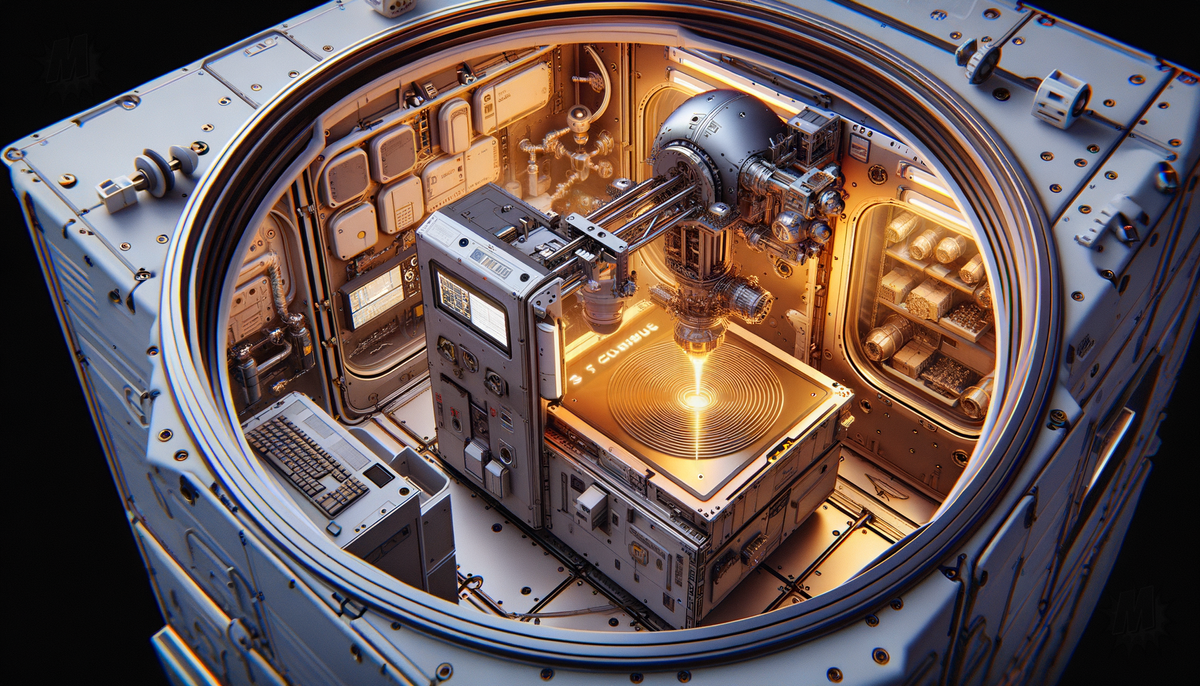

Space Station achieves first-ever metal 3D printing milestone

The European Space Agency (ESA) has successfully completed the first metal 3D printing aboard the International Space Station (ISS). The printing took place in the ESA’s Columbus laboratory module using a technology demonstrator developed by Airbus under a contract from ESA's Directorate of Human and Robotic Exploration. The printer employs a directed energy deposition (DED) process, where stainless-steel wire is heated by a high-power laser to create metallic parts. This initial test involved the creation of an S-curve test line, marking a significant advancement for in-orbit manufacturing.

The project, known as "Metal3D," aims to develop the capability to manufacture tools and components directly in space, reducing the need for resupply missions from Earth. The printer operates within a fully sealed box to contain heat and fumes, ensuring safety aboard the ISS. The ESA plans to analyze the printed parts in their Materials and Electrical Components Laboratory in the Netherlands to study the effects of prolonged microgravity on metallic materials. The long-term goal includes creating a circular space economy by using recycled materials from old satellites and space debris to fabricate new tools and structures.