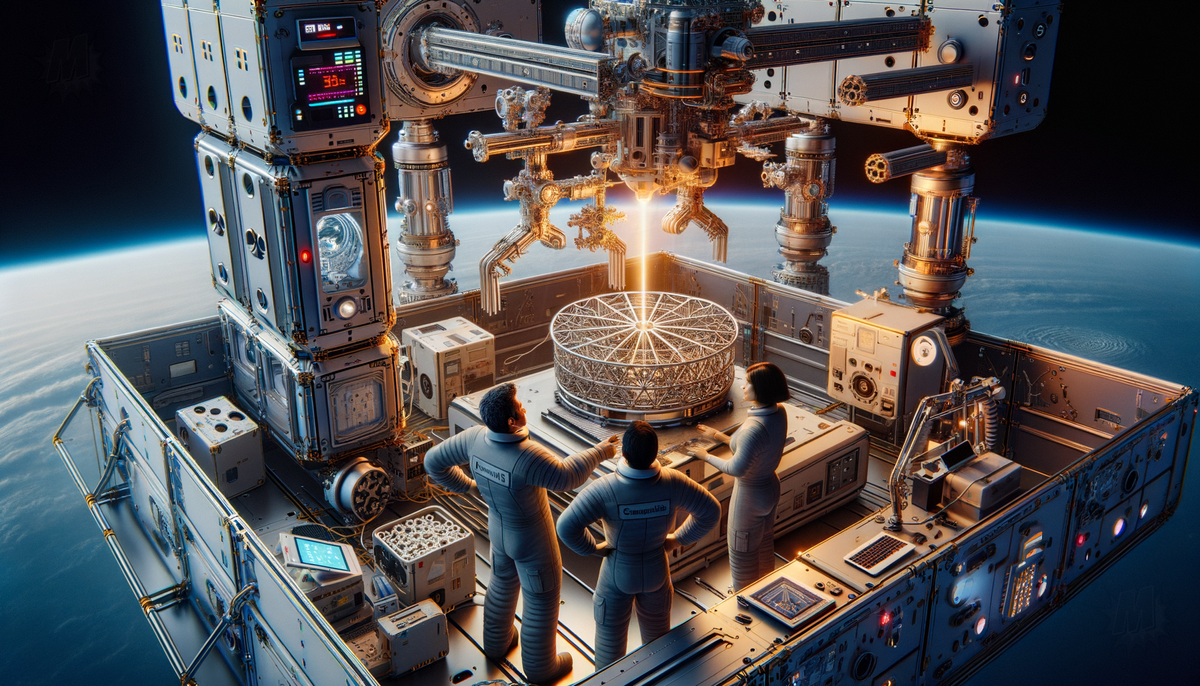

ESA Achieves First 3D Printing of Metal Part in Space

The European Space Agency (ESA) has successfully produced the first metal part using a 3D printer aboard the International Space Station (ISS). This achievement, completed in August 2024, marks a significant step in developing in-space manufacturing capabilities, which could enhance crew autonomy for long-duration space missions. The 3D printer, developed by ESA in collaboration with Airbus and Cranfield University, was installed in the Columbus module of the ISS and uses a laser to melt stainless steel wire, creating high-strength parts in a microgravity environment.

The printing process was initiated in May 2024 and involved the coordination of specialists from the French space agency CNES and Airbus. The first printed sample, consisting of over 200 layers of metal, will be returned to Earth for quality analysis at various ESA facilities and the Technical University of Denmark (DTU). This project not only demonstrates the feasibility of producing durable parts in space but also opens up possibilities for future on-orbit manufacturing, potentially reducing reliance on Earth-based resupply missions and enhancing the viability of deep space exploration.